- New

GRANULITE SANDPOOL is a two-component product based on polyurethane water, which is presented as component A in the form of a semi-solid paste, practically odorless, ready for mixing with component B, a catalyst that appears as a viscous liquid, which is transformed, once applied on the support, in a TRUE EPIDERMIS (or FILM OF MARBLE GRANULES and SILICONE) perfectly adhered to the support.

It is a continuous coating of 3 mm natural stone without joints. Two-component product based on water-based polyurethane, which is presented as component A in the form of a semi-solid, practically odorless paste, ready to be mixed with component B catalyst.

20kg A + 0.5kg B

** Very important, never apply this product under direct sun, avoid applying at high temperatures.

It is a two-component product based on polyurethane water, which is presented as component A in the form of a semi-solid, practically odorless paste, ready to be mixed with component B, a catalyst that is presented as a viscous liquid, which transforms once applied. on the support, in a TRUE EPIDERMIS (or MARBLE GRANULE FILM) perfectly adhered to the support.

PRESENTATION

GRANULITE SAND POOL is a two-component water-based polyurethane product, which is presented

as component A in the form of a semi-solid, practically odorless paste, ready for mixing

with component B, a catalyst that appears as a viscous liquid, which is transformed, once

applied on the support, in a TRUE EPIDERMIS (or MARBLE GRANULE FILM)

perfectly adhered to the support.

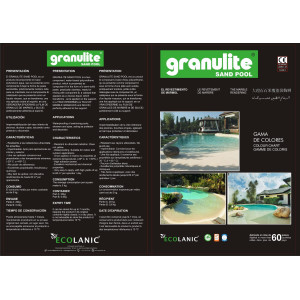

COLORS

The ones in the sample book. Natural stone colors (undyed) may vary slightly or

color shifts due to the very nature of the marble granule.

APPLICATIONS

For indoor/outdoor flooring and swimming pools, acting as a protector and decorator.

ASPECT

Beauty adapted to modern aesthetic trends.

COMPOSITION

GRANULITE is a conglomerate of different epoxy resins and marble and silica granules.

CHARACTERISTICS

- Resistant to ultraviolet radiation. Does not yellow

- Raincoat. Suitable for outdoor applications

- Once applied, it retains its properties at extreme temperatures (-20º C. to +60º C.)

- High adhesion power

- Excellent mechanical and chemical properties

- Very easy to apply, with high yields of up to 60 m² per operator/day.

TECHNICAL DATA

Color: PART A: According to color sample. PART B: Transparent

Pot life: 25 – 35 minutes

Application temperature: Between 10ºC and 25ºC

Viscosity: Low viscosity liquid

Density: 1.05 gr./cm3

Passable: 12 hours at 20ºC

Solids content: 100% by weight

APPLICATION TOOLS

The work containers used (buckets, pastries, etc.) must be plastic. The tools

application must be made of stainless steel.

SUPPORTS

GRANULITE can be applied on a wide variety of surfaces with characteristics different:

- Cement mortars, self-leveling, etc., as long as they are in good condition.

- Smooth walls of concrete removed from formwork and clean of release agents.

- The preparation will be by milling, shot blasting or sanding, depending on the support and the

subsequent treatment.

- The support must be firm (minimum tensile strength of 1.5 N/mm2 and a compression

minimum of 20 N/mm2), clean of dust, grease, oil, rest of old paint and dry

(maximum permitted humidity 4%).

- For application in swimming pools, the pool glass must be waterproofed with our

MR NOWA waterproofing agent leaving a rough surface to improve adhesion on the

vertical walls.

ORDER OF APPLICATION

1st Primer of the support. PRIMER Dur.

Apply a layer of PRIMER DUR (see technical sheet) on the support to promote perfect

anchoring the final product.

It is distributed over the surface, with the help of a brush, roller or airless, so that it impregnates

homogeneously and completely the support.

The formation of puddles of product on the surface must be avoided.

It is presented in containers with the appropriate proportions for the application.

Consumption as a sealing layer for highly porous supports is 150 gr./m2.

Drying time is relative and depends on the atmospheric conditions in each case.

Once it is dry, we can apply the layer of GRANULITE SAND POOL on top.

2nd GRANULITE SAND POOL

After the preparation described above we can apply GRANULITE SAND POOL

MIXED

It is presented in containers with the appropriate proportions for mixing the two components.

In no case are partial mixtures recommended. Component B is added to the

Component A and mix at low revolutions (300 – 350 revolutions) for 3-5 minutes

using a drill fitted with an agitator, until a homogeneous product is obtained. This process

It is important not to heat the mixture and that could cause a rapid drying reaction of the

the same. Air entrapment must be avoided during mixing.

APPLICATION

Spread the product with the help of a metal trowel and go over it in the same direction to

avoid marks. The ease of application of the product allows for the creation of continuous surfaces of one

once. The joining of cloths, whether of the same color or different tones, can be done without

problems, although metal profiles can be used.

On vertical walls, the application of the material is done from bottom to top on the surface.

of work of the worker.

The trowels used are of different shapes, depending on the imperatives of the work. (steel

stainless).

The working time is 30 minutes depending on the temperature and hygrometric state. During this

working time, proceed to tamp the marble granules and smooth the GRANULITE FLOOR

using the same trowel.

GRANULITE SAND POOL should not be applied at temperatures below +10ª C. nor above

25º C.

Use the complete product once opened. Do not knead the material again or add any

other product.

The product usually dries to the touch after 12 hours and can be walked on after 24 hours at a

average temperature of 20º C. Its maximum hardness is reached after 7 days.

CONSUMPTION

The average consumption per square meter is 5 kg.

CONSERVATION

GRANULITE is washable using liquid detergents (neutral or acidic) diluted with water

(according to the manufacturer's instructions) and then proceeding to brush (soft bristle) and

rinsed with clean water.

CONTAINER

Part A: 20kg

Part B: 0.6kg

CONSERVATION TIME

It can be stored for up to 7 months, keeping the product in its original container tightly closed.

in a dry place. It is not advisable to store the product at temperatures below 10 ºC.

HANDLING

Polyurethane resins can cause irritation in people with sensitive skin, so they should be

It is recommended to use rubber gloves, protective glasses and a mask during handling. In

In case of contact with eyes, wash them with plenty of clean water and consult a doctor. The

Hands and skin should be washed with hot water and soap. Avoid release to the environment.

Here you can add custom original content(text, images, videos and more) for each product page.

2 other products in the same category:

INSTRUCTIONS FOR USE APPLICATION WITH BRUSH:1.- Component “B” (1 part of 10Kg liquid) is poured into a clean container, and component “A” is added gradually.(2 parts of solid. 20Kg). Mix it (300 to...

GLOBALFIX is a single-component, flexible, powder gel-adhesive with increased open time and zero vertical slip, designed for bonding all types of ceramic and glass mosaic tiles. Particularly...

error Your review appreciation cannot be sent